Welcome to School of Civil Engineering With S.M. Hedaetullah Bin Siddik And NJ DishaNote: Full Credit to Owners. All Images, Picture, Music show in the video.

Mini CAD Viewer is a compact free CAD Viewer that allows you to move and zoom in and out and to draw as needed on current view. The program features 'thumbnail' view, which allows users quickly perform searches on task folders. It supports DWG, DWF and DXF formats and drawing files can be printed. Copypod V9 48 Crack Hp Photosmart 3300 Series Download Memory Map 5 4 2 Crackheads Tviewer Beta 1.0 Crack Om Sai Mantra Cisco Usb Console Driver Scesp4i.exe Download Armaan Malik Songs List Sen Gil Puyat Ave Makati City Zip Code Download Game Ultraman Evolution 3 Tasikgame Rgs Rebar Software With Crack. How to activate any software license keyfree activation keyshow to crack software license key tutorialactivation key generatorhttps://vacnic.comhttps://www.f.

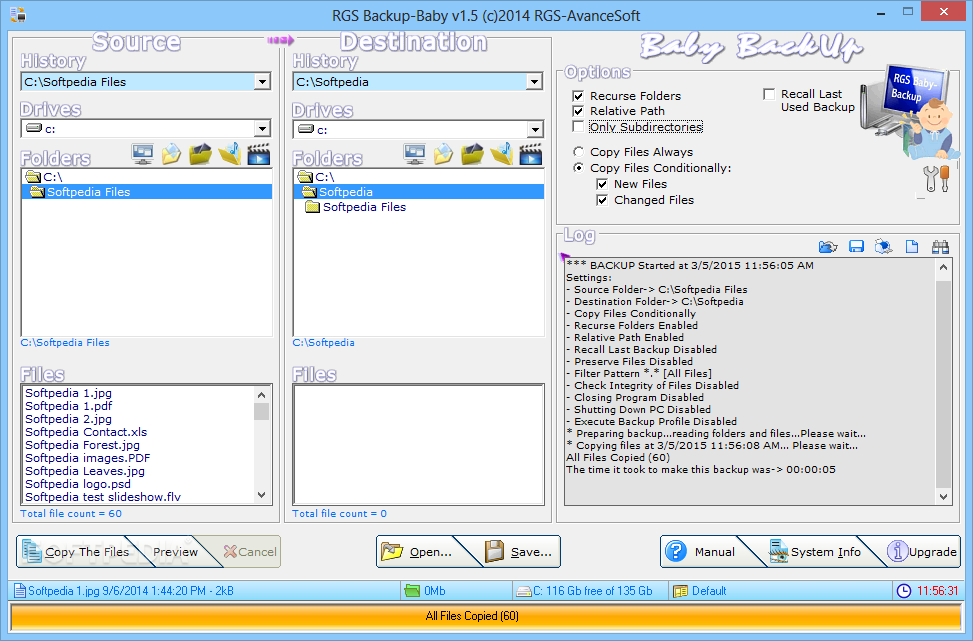

Rgs Rebar Software Free With Crack

Your reputation as a High quality and a trustworthy detailer/detailing company is very important to progress in your career in detailing. Establishing such a high reputation is not easy. There is a famous saying that your reputation lies in the last drawing you have submitted.Yes. Unfortunately, you have to ensure that each and every submittal you make should be thorough and fool proof. It's difficult to maintain consistent quality in Rebar detailing but is not impossible.

1. You must have the attitude to deliver quality. It should be in your DNA.

2. You must have a detailing and project management process and verbatim implement it on every drawing/every job.

The management gurus will say that Quality and productivity are always interrelated. If you want to achieve excellent productivity, you have to 'Do it right the first time'. Once you follow this 'Manthra', you can see that you will have a significant gain in your detailing productivity also. This is also applicable for Rebar detailing companies. Please have a detailing process in place and educate your detailers to understand the need for a Process.

A professional detailer of high reputation should not require someone to check his/her work. They know how to maintain his/her quality by themself. They don't need any support and hence they always do a Great job.

How to do it right the first time?

Here I am going to share a checklist. I assure that I will share the support documents in my subsequent posts.

1. Ensure that you have received the latest set of structural and architectural drawings.

It's quite normal that you get an obsolete drawing and someone would have wrongly sent you that for detailing. You need to double check with the client and ensure that what you have is the latest. Keep communicating with the client and always mention the reference structural drawing number, revision number and date while you prepare the Placing drawings.

When the site work is prepared based on a new set of drawings that you did not receive and if the Rebar is fabricated based on your bar list. The problem starts. You need to fix the problem, whether you are right or wrong. Who cares if you are right and the client did not send you the latest drawings. So Please be vigilant about the structural drawings you are using for detailing.

Its quite common that one job has multiple scopes and different fabricators might be doing it. So if you are asked to detail a job and asked to do foundations, please list the structural elements and check if it is under your scope. Many times Piles are done by different group. You will not be paid. Its your mistake on not to ask. Got it.

3. Understand the construction schedule, Detailing preferences, drawing presentation standards of your client.

If you do not know the construction schedule of your project then you may not be able to service. So its very important to nag the client and get these dates continuously. You have to also ask about the concrete pouring status of areas detailed and submitted and check if any difficulties are faced by the Rebar placer. This will be a good practice and your client will know that you are involved and not taken his job lightly.

You should also know your clients detailing preferences. You may detail all stock bars as 30-0 and after you submitted, the client may want you to use 40-0 as stock length. Or the client may ask you to go for couplers for certain bar sizes and above, where as you would have detailed with normal laps. Some jobs need alternating laps where you would not have done that. All these are Rework and Waste of time.so ask all questions before starting a job.

The Presentation standards I have seen the best so far are for U.K and middle east. The British civil engineers are very particular about the presentation styles of placing drawing. You have to understand their concept. They want everything to be presented in such a way so that they can check a drawing with out directly interacting with the detailer.Whereas as per CRSI a Rebar Placing drawing need not contain Concrete Dimensions because they are going to be placed on the form work and dimensions are take care by them.

I am not going to comment on both. Its their choice. So ask your client on the Presentation standards to be followed on their Rebar Placing drawings.

4. Prepare project notes before starting the new job.

Before starting any detailing project, please prepare a Project notes. Project notes is a summary of varies items like Scope of work, Splicing details, Stock lengths, Special notes or instructions given in the structural drawings, sections to be used for detailing and many things. If any of this information is not followed, then you end up correcting the drawing later. So project notes is where you list the vital information required to do the job and if that is double checked, you drawing may not have blatant mistakes. I repeat. If project notes is correctly prepared you can do an error free detailing. If you are a project manager or a Team leader then you should check the project notes of your team and ensure it is updated when you get revised structural drawings.

I will share a sample Project notes in my subsequent postings. It will be very useful for you.

5. Have a complication matrix and Check it in your current project.

The Second Page of a Sample Complication Matrix for Wall

Its very common that a detailer will miss a step, slope or a pocket etc when they detail. So how do you ensure that they have studied the structural drawing in depth and noted all such complications? We have prepared a checklist that lists all possible complications in a structural element and a detailer must check if these complications are present the project and make a note of it. Trust me, this practice fixed the issues. Even if you are an experienced detailer my recommendations don't change. I will follow carpenters rule .Measure twice and cut once. How to add line numbers in microsoft word for mac.

6. Check if the cad drawings provided by the client, is to scale.

Rgs Rebar Software Free With Crack Version

It's a custom that the structural drawings received are used as base drawings. That is why the structural engineers hesitate to send the CAD files. But many detailers convert from PDF to CAD and still use that. It could be a copyright violation. Please get written approval from the engineers to use the drawings.

Please note .you have to double check the Drawing Scale, before using them. Otherwise it will be a rework.

7. Print/Append all the communications with the client in a single PDF file.

Usually the detailer will be subjected to a blame game at the end of the project, when his extras needs to be paid. So, in order to protect yourself and earn for the legitimate time you have contributed in a job, you need to quote the email or any other communication you had with the client and provide as supporting documents. Its very normal to get replies like 'Sorry.He just verbally asked me to do like that and I was very busy to complete the job, so I dint send a conformation email.etc'.,

You should have a communication digest of every job in PDF separately. Even if you chat in whats app or skype , please archive it. If you speak over phone, send email confirming the points discussed. That's how professionals work.

8. Never assume things. Raise RFI. Don't wait for the response( Exceptional cases are there), complete the drawing, Cloud the assumptions and flag it for engineers review/approval with the Item no and RFI #.

Sending a RFI and also clouding in the drawing, referring the RFI is the best practise. Also note that your RFI should be as pictorial as possible. Your clients are extremely busy and are running out of time.You want them to answer.so make your question smart. Let them not read it .Just let them see a picture and reply.

I will try to post few RFI's for your reference.

9.Check placing drawings with project notes and complication matrix to avoid major errors in 15 minutes.

I will share a sample Project notes in my subsequent postings. It will be very useful for you.

5. Have a complication matrix and Check it in your current project.

The Second Page of a Sample Complication Matrix for Wall

Its very common that a detailer will miss a step, slope or a pocket etc when they detail. So how do you ensure that they have studied the structural drawing in depth and noted all such complications? We have prepared a checklist that lists all possible complications in a structural element and a detailer must check if these complications are present the project and make a note of it. Trust me, this practice fixed the issues. Even if you are an experienced detailer my recommendations don't change. I will follow carpenters rule .Measure twice and cut once. How to add line numbers in microsoft word for mac.

6. Check if the cad drawings provided by the client, is to scale.

Rgs Rebar Software Free With Crack Version

It's a custom that the structural drawings received are used as base drawings. That is why the structural engineers hesitate to send the CAD files. But many detailers convert from PDF to CAD and still use that. It could be a copyright violation. Please get written approval from the engineers to use the drawings.

Please note .you have to double check the Drawing Scale, before using them. Otherwise it will be a rework.

7. Print/Append all the communications with the client in a single PDF file.

Usually the detailer will be subjected to a blame game at the end of the project, when his extras needs to be paid. So, in order to protect yourself and earn for the legitimate time you have contributed in a job, you need to quote the email or any other communication you had with the client and provide as supporting documents. Its very normal to get replies like 'Sorry.He just verbally asked me to do like that and I was very busy to complete the job, so I dint send a conformation email.etc'.,

You should have a communication digest of every job in PDF separately. Even if you chat in whats app or skype , please archive it. If you speak over phone, send email confirming the points discussed. That's how professionals work.

8. Never assume things. Raise RFI. Don't wait for the response( Exceptional cases are there), complete the drawing, Cloud the assumptions and flag it for engineers review/approval with the Item no and RFI #.

Sending a RFI and also clouding in the drawing, referring the RFI is the best practise. Also note that your RFI should be as pictorial as possible. Your clients are extremely busy and are running out of time.You want them to answer.so make your question smart. Let them not read it .Just let them see a picture and reply.

I will try to post few RFI's for your reference.

9.Check placing drawings with project notes and complication matrix to avoid major errors in 15 minutes.

After completing the detailing, just check the Rebar placing drawing with project notes and complication matrix. This will ensure that you have detailed the project as per the engineers intent specified in structural drawings.Since all major points are covered, the drawing will not have major errors. Checking with project notes still you to check the placing drawings minor errors if any.

Still you have to check the placing drawings with the structural drawings.

10. Rebar wastage analytics and Optimised Bar Bending Schedule

Run the optimization module in RGS REBAR after checking the drawing with project notes. You will understand the potential scrap generatable from your drawing. Professional detailing companies readjust the detailing and ensure that the scrap levels are minimal. It's just an ignorance to believe that the fabricator will take care of wastages when they run the optimization programs in the shops. They can only reuse offcuts there.

Actually, the scrap can be eliminated only by attending to each Bar bending schedule very carefully and reducing it. The bbs/barlist thus generated is 'Optimised Bar bending schedule'. The fabricators or contractors can pay few $ extra for this valuable service that will reduce rebar wastage.

RGS Rebar has the facility to upload a reusable offcut Rebar data and Run optimization to check, how far the existing offcuts can be reused.

I will cover a separate article on REBAR WASTAGE analytics in my forthcoming articles. Telecharger autocom cdp delphi keygen.

So please read and re-read my articles till you catch my thoughts. You will certainly find my approach work wonders for you or your company. I worked in many small and many very large projects from different countries. This is a snapshot of my experience for the past 20 years as a detailer, Team leader , project manager , as a owner, as a system analyst, software developer and a product designer. In all these roles my goal was always to reduce error and increase productivity of detailing and prepare a Placer friendly Placing drawings and Optimised Bar lists/Bar Bending schedule.

Please share this blog with students/freshers and your colleagues.World needs more and more professional Rebar detailers of High reputation. Post your comments also. I will reply when possible.